Compressed Air Pressure Drop: The Hidden Cost Draining UK Industrial Businesses

What Is Pressure Drop in a Compressed Air System?

Pressure drop occurs when compressed air loses pressure between the compressor and the point of use.

In industrial environments, this is commonly caused by:

Undersized or outdated compressed air pipework

Corroded steel pipes restricting airflow

Poor system layout with excessive bends and restrictions

Incorrect fittings, couplings, and connectors

High-demand tools operating at the end of long pipe runs

When pressure drops, businesses compensate by turning the pressure up — forcing the compressor to work harder than necessary.

How Pressure Drop Increases Energy and Running Costs

For every 1 bar increase in system pressure, energy consumption rises by approximately 7%.

That means:

Higher electricity bills

Increased compressor run hours

More frequent servicing and breakdowns

Reduced lifespan of compressors and tools

Many UK businesses assume their compressor is underpowered, when in reality the compressed air system design is the real issue.

Why Most Industrial Sites Never Fix the Root Cause

Traditional air compressor suppliers focus on selling machines — not optimising the entire system.

Pipework, air distribution, and demand profiling are often overlooked, leading to oversized compressors, wasted energy, and ongoing performance issues.

Air Demand takes a different approach.

How Air Demand Improves Compressed Air Efficiency

We start by understanding air demand, not just compressor size.

Our solutions typically include:

✔ Optimised Compressed Air Pipework

We supply and install modern galvanised and aluminium pipe systems that reduce friction, prevent internal corrosion, and maintain consistent pressure across your site.

✔ Smarter System Design

Correct pipe sizing, ring mains, efficient routing, and properly positioned drops ensure air reaches tools without unnecessary pressure loss.

✔ Correct Compressor Matching

We ensure your air compressor matches real demand — avoiding oversizing, excessive cycling, and wasted energy.

✔ Long-Term Cost Reduction

Lower operating pressure, reduced energy usage, fewer breakdowns, and predictable performance.

The Commercial Benefits of Fixing Pressure Drop

Businesses that address pressure drop in their compressed air systems often achieve:

Immediate improvement in tool performance

Reduced system pressure by 0.5–1 bar

Lower energy costs

Extended compressor lifespan

Avoided capital spend on unnecessary upgrades

All without replacing the compressor.

Industrial Compressed Air Solutions That Make Sense

If your tools feel underpowered, operators keep adjusting pressure, or energy bills continue to rise, pressure drop is likely costing your business more than you realise.

Air Demand Ltd provides practical, system-wide compressed air solutions for UK industrial businesses — focused on efficiency, reliability, and long-term savings.

Smarter air. Lower costs. Better performance.

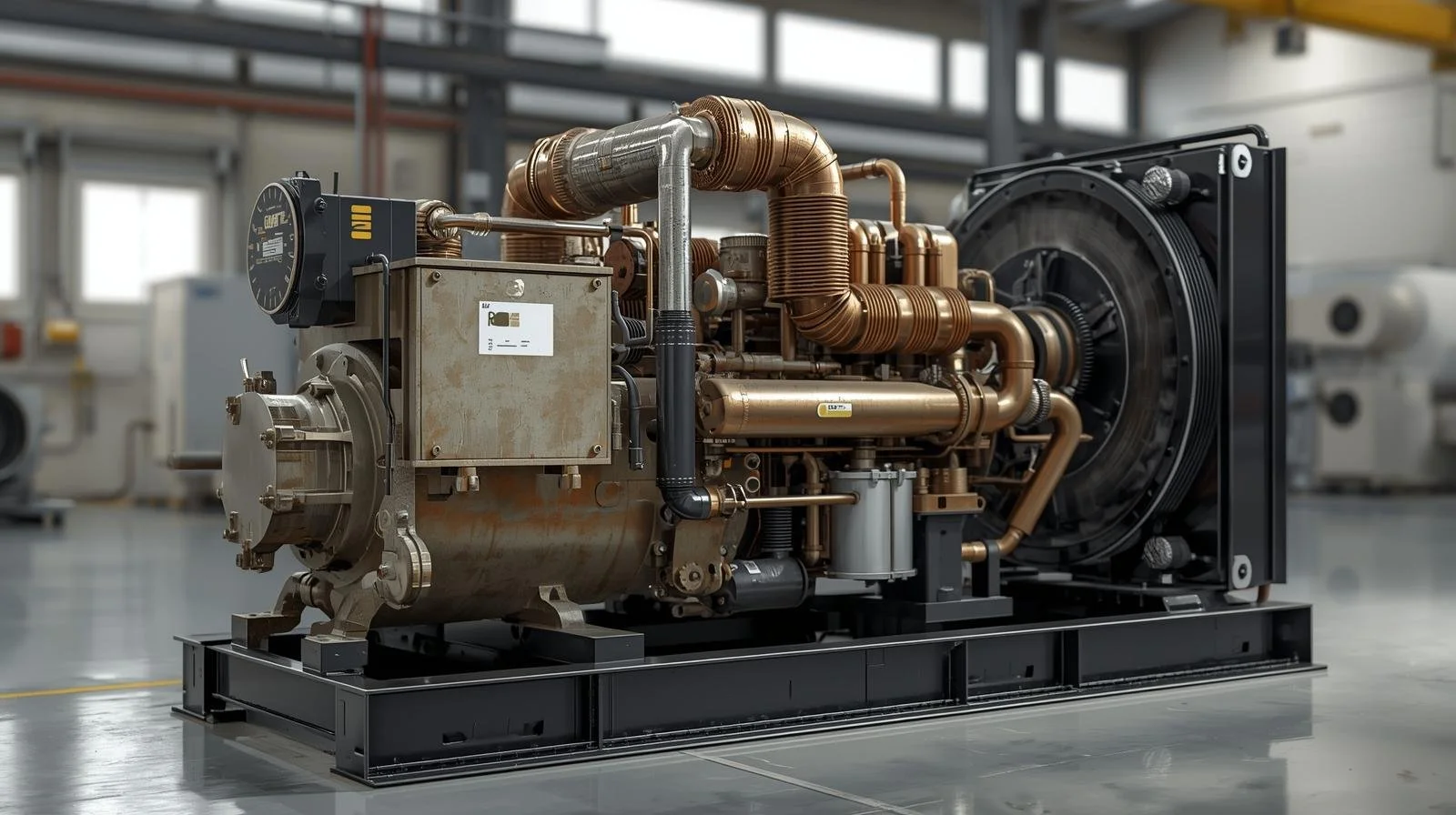

oil lubricated rotary screw air compressor for industry

oil lubricated rotary screw air compressor

Running a busy workshop or factory comes with its fair share of challenges, but one of the biggest headaches is unreliable compressed air. Machines that falter mid-shift can cost time, money, and frustration. That’s why so many professionals are turning to the oil lubricated rotary screw air compressor, a powerhouse designed to handle heavy workloads continuously while reducing maintenance stress. At AirDemand, our EG Series delivers the perfect blend of durability, efficiency, and reliability, helping your operations run smoother every day.

Why Oil Lubricated Screw Compressors Are a Game-Changer

How Does an Oil Lubricated Rotary Screw Air Compressor Work?

An oil lubricated rotary screw air compressor may sound technical, but it’s brilliantly simple in operation. The compressor uses two interlocking screws, called rotors, to compress air. Oil circulates through the system, providing three key benefits: lubrication, cooling, and sealing. This makes the compressor highly efficient and long-lasting, especially in environments where it’s running constantly.

Compared to oil-free models, oil lubricated screw compressors are much more robust. They maintain airflow and pressure under heavy loads, making them ideal for workshops, manufacturing plants, and large industrial facilities. The EG Series even uses ELGi’s η-V airends and advanced OSBIC oil separation, reducing oil carryover while increasing efficiency.

ELGi EG Series screw air compressors

Benefits You’ll See in Your Workshop

Investing in an oil lubricated screw air compressor has tangible benefits:

High Efficiency: Advanced motor and airend designs reduce electricity consumption.

Long-Lasting Durability: Continuous lubrication prevents wear on critical components.

Low Maintenance: The OSBIC oil separation system simplifies upkeep.

Reliable Performance: Delivers consistent air pressure even during long operations.

Reduced Noise: Modern designs ensure quieter operation compared to older screw compressors.

Cost Savings: Less downtime and energy consumption translate to reduced operational costs.

For businesses running multiple machines or heavy-duty equipment, an oil lubricated screw air compressor isn’t just convenient, it’s a vital investment.

Choosing the Right Oil Lubricated Screw Compressor

Match Your Air Needs to the Right Model

Not all compressors are created equal. When choosing an oil lubricated rotary screw air compressor, consider:

Air volume requirements: How many cubic feet per minute (CFM) do your tools need?

Operating hours: Will the compressor run 24/7 or only part-time?

Physical space: Do you have room for a larger stationary unit, or do you need a compact model?

The EG Series from AirDemand offers multiple models to suit different needs, from workshops to industrial facilities. Each is engineered for reliability and energy efficiency, making it easier for you to find the perfect match for your business.

Maintenance Tips for Long-Term Reliability

Even the best oil lubricated screw compressors benefit from a little TLC:

Regular Oil Changes: Follow the manufacturer’s schedule to keep the system lubricated.

Temperature Control: Ensure your compressor is in a well-ventilated area to prevent overheating.

Filter Checks: Clean or replace air and oil filters to maintain efficiency.

Inspect Hoses and Fittings: Prevent leaks that could reduce performance.

Proper maintenance not only prolongs the life of your oil lubricated rotary screw air compressor but also ensures your team can rely on it day in and day out.

Applications for Oil Lubricated Screw Air Compressors

Oil lubricated screw compressors are versatile and used across many industries:

Automotive repair and service shops

Manufacturing and assembly lines

Food and beverage production

Textile and garment factories

Pharmaceutical facilities

Large-scale construction projects

Wherever continuous, reliable compressed air is required, an oil lubricated screw air compressor is a smart choice. Its ability to operate without frequent stops or maintenance makes it indispensable for high-demand environments.

Why Choose AirDemand for Your Compressor

At AirDemand, we don’t just sell compressors, we help you find the right solution for your specific needs. Our EG Series oil lubricated screw compressors are selected for their durability, energy efficiency, and low cost of ownership. We provide guidance to ensure you choose the right model and support you throughout your compressor’s lifespan.

Check out the EG Series here: AirDemand EG Series

Frequently Asked Questions

1. What is an oil lubricated rotary screw air compressor?

It’s a compressor that uses interlocking screws and oil for compression, lubrication, and cooling. ideal for continuous industrial use.

2. How does it differ from oil-free compressors?

Oil-lubricated models are more durable and efficient under heavy loads. Oil-free compressors are quieter and cleaner but less suitable for continuous, high-volume use.

3. What maintenance is required?

Regular oil changes, filter inspections, and hose checks are key to keeping your compressor in top shape.

4. Are these compressors energy-efficient?

Yes. Modern designs like the EG Series focus on reducing energy use while maintaining consistent output.

5. Can they be used in small workshops?

Absolutely, just choose a model that matches your air volume needs.

6. How long do these compressors last?

With proper maintenance, an oil lubricated screw air compressor can last 15 years or more.

7. Are they noisy?

They are quieter than older models, though generally louder than small oil-free units.

8. Where can I purchase one?

You can explore and order directly from AirDemand: EG Series Compressors

A reliable oil lubricated rotary screw air compressor is more than just a piece of machinery, it’s the heartbeat of your workshop or factory. The EG Series from AirDemand combines efficiency, durability, and low maintenance to give you the performance your business needs. With proper care, these compressors provide years of uninterrupted service, helping you focus on what really matters: keeping your operations running smoothly.

Ready to upgrade your compressed air system? Explore the EG Series now and see how it can transform your workshop today!

Nuair Air Compressor: The Smartest Investment for Your Workshop

nuair air compressor

When it comes to keeping your workshop or industrial facility running smoothly, few tools are as crucial as a reliable Nuair air compressor. Whether you’re powering pneumatic tools, filling tyres, or running production machinery, a high-quality air compressor can save you time, reduce operational headaches, and even lower energy costs. But are Nuair air compressors any good? Let’s dive in and explore why they’re trusted by professionals across the UK.

What Makes a Nuair Air Compressor Stand Out?

A Nuair air compressor is engineered with precision, durability, and energy efficiency in mind. Unlike generic models, these compressors are built to handle continuous use without frequent breakdowns. Whether you’re looking for a compact solution for your workshop or a larger model for industrial purposes, Nuair has a machine designed to meet your needs.

Nuair compressors come in both piston and rotary screw designs, including the popular oil-lubricated models like the EG Series we stock at AirDemand. These compressors feature advanced motor and cooling systems, ensuring reliable operation and long service life. The combination of energy efficiency and robust construction makes Nuair air compressors a smart choice for professionals who demand consistent performance.

Key Benefits of Choosing Nuair

Reliability: Built to withstand heavy-duty applications.

Energy Efficiency: Designed to minimise electricity usage.

Low Maintenance: Durable components and easy-to-service design.

Versatility: Suitable for automotive, industrial, and commercial applications.

Quiet Operation: Advanced design reduces noise during operation.

When you choose a Nuair air compressor, you’re investing in equipment that will keep your business running smoothly, day after day.

Are Nuair Air Compressors Any Good?

Many business owners ask, “Are Nuair air compressors any good?” The short answer is yes. Nuair has a strong reputation in the UK and Europe for producing reliable, energy-efficient compressors that last. From workshops to large manufacturing facilities, these machines provide consistent airflow and pressure, ensuring that your operations never have to pause due to equipment failure.

The EG Series of oil-lubricated rotary screw compressors we offer at AirDemand is a prime example. These units combine ELGi’s η-V airends with a unique OSBIC oil separation system, advanced intake valves, and next-generation cooling systems. The result is a compressor that’s not only efficient but also built to last, with low total cost of ownership.

Why Professionals Trust Nuair

Continuous, reliable airflow for demanding tasks

Easy integration with workshop setups and pneumatic systems

Reduced operational costs due to energy efficiency

Durable construction ensures minimal downtime

For anyone asking whether Nuair air compressors are any good, the answer is reinforced by their widespread use in workshops, factories, and service centres across the UK.

Choosing the Right Nuair Air Compressor

Selecting the right Nuair air compressor depends on your specific requirements:

Air Volume: Determine how many cubic feet per minute (CFM) your equipment needs.

Operating Hours: Are you running the compressor continuously, or just intermittently?

Power Source: Decide between electric or diesel models based on your workspace setup.

Space Considerations: Ensure the compressor fits comfortably in your workshop or facility.

Our EG Series oil-lubricated screw compressors are ideal for businesses requiring continuous high-volume air. With models to suit different capacities, they’re engineered to meet demanding industrial needs while maintaining energy efficiency.

Tips for Long-Term Maintenance

Even the best Nuair air compressors need proper maintenance:

Regular Oil Checks: Keep your oil-lubricated models topped up to avoid wear.

Filter Replacements: Maintain air quality and efficiency.

Temperature Monitoring: Ensure compressors have adequate ventilation.

Inspect Hoses and Connections: Avoid leaks that reduce performance.

With proper care, your Nuair air compressor can provide years of dependable service, making it a long-term investment in your business efficiency.

Applications for Nuair Air Compressors

Nuair air compressors are incredibly versatile. Industries and applications include:

Automotive repair and service workshops

Industrial manufacturing plants

Food and beverage production lines

Construction sites

Textile and garment factories

Pharmaceutical facilities

Anywhere reliable compressed air is needed, a Nuair air compressor can provide the consistent performance necessary to keep operations running smoothly.

At Air Demand, we stock a variety of Nuair compressors, including the EG Series oil-lubricated screw compressors. Our team can guide you in choosing the right model for your workshop or industrial facility.

Check out the full range here: EG Series Nuair Compressors

FAQs About Nuair Air Compressors

1. What is a Nuair air compressor?

A high-quality compressor designed for workshops and industrial use, available in piston and rotary screw models.

2. Are Nuair air compressors any good?

Yes. They are widely trusted for reliability, efficiency, and low maintenance requirements.

3. What is the difference between oil-lubricated and oil-free Nuair compressors?

Oil-lubricated models offer continuous high-volume airflow and durability, while oil-free models are quieter and cleaner for sensitive applications.

4. How often should I service a Nuair air compressor?

Regular oil checks, filter replacements, and inspections every few months ensure longevity and efficiency.

5. Can Nuair compressors handle continuous operation?

Yes. The EG Series, for example, is designed for uninterrupted industrial use.

6. How energy-efficient are Nuair compressors?

Very. They feature advanced airend and cooling technologies to reduce electricity consumption.

7. Can I use a Nuair air compressor in a small workshop?

Absolutely. Choose the right capacity model to suit your air volume needs.

8. Where can I buy a Nuair air compressor?

AirDemand stocks a full range of Nuair compressors: EG Series Nuair Compressors

If you’re serious about keeping your workshop or industrial operation running efficiently, investing in a Nuair air compressor is a smart choice. Their reputation for reliability, energy efficiency, and durability makes them one of the most trusted brands in the UK.

Industrial Elgi Air Compressors

Industrial Elgi Air Compressors deliver powerful, energy-efficient compressed air solutions, ideal for factories, workshops, and heavy-duty industrial use.

Industrial Elgi Air Compressors: Efficient and Durable Solutions

Choosing the right industrial compressor is crucial for any workshop or production environment. Industrial Elgi Air Compressors available on Air Demand provide a balance of reliability, energy efficiency, and long-term performance. Designed for continuous operation, these compressors ensure stable airflow, clean output, and minimal maintenance, making them an ideal choice for businesses that depend on a consistent compressed air supply.

What Are Industrial Elgi Air Compressors?

Industrial Elgi Air Compressors, particularly the EG Series, are oil-lubricated piston compressors engineered for high performance and durability. According to the Air Demand product page, these compressors deliver reliable air output, are easy to maintain, and offer efficient operation. Their robust construction ensures long service life, making them suitable for workshops, manufacturing plants, and heavy-duty industrial applications.

Key Features of EG Series Compressors

Oil-Lubricated Design: Ensures smooth operation and reduces wear on moving parts.

High Efficiency: Optimized for energy savings while maintaining stable airflow.

Durable Build: Robust materials and precision engineering guarantee reliability over years of use.

Low Maintenance: Easy access to key components helps reduce downtime and servicing costs.

Why Choose ELGI Compressed Air Products

ELGI Compressed Air Products are trusted worldwide for their consistent performance and low total cost of ownership. Choosing genuine ELGI products means you get compressors designed for maximum efficiency, reduced energy consumption, and reliable operation. The EG Series, in particular, is highlighted on Air Demand for its balance of power and durability, suitable for both small workshops and industrial facilities with higher demand.

Benefits of ELGI Compressed Air Products

Energy Efficiency: Optimized piston mechanisms reduce power usage while maintaining performance.

Longevity: High-quality materials and precise engineering extend the life of the compressor.

Versatility: Suitable for a wide range of applications, from workshops to industrial plants.

Support and Service: Purchasing through Air Demand ensures access to technical advice and genuine spare parts.

Comparing Industrial Elgi Air Compressors to Other Options

Air Demand offers a variety of compressed air solutions, but Industrial Elgi Air Compressors stand out due to their combination of reliability and energy efficiency. While other piston compressors may suffice for light or occasional use, the EG Series is designed for continuous operation, making it ideal for businesses with steady compressed air requirements. Air Demand shop provides easy navigation to compare different models and select the right compressor based on your operational needs.

When to Choose an EG Series Compressor

Continuous heavy-duty operations that require reliable air supply.

Workshops and plants where energy efficiency and low maintenance are priorities.

Facilities that need access to genuine ELGI spare parts and technical support.

Maintenance Tips for Industrial Elgi Air Compressors

Proper maintenance ensures that your EG Series compressor continues to operate efficiently over its lifetime. According to Air Demand, regular checks of oil levels, filters, and pressure systems can prevent downtime and costly repairs. Using genuine ELGI Compressed Air Products for replacement parts further guarantees compatibility and optimal performance.

Recommended Maintenance Practices

Check and replace oil regularly to ensure smooth operation.

Inspect air filters and clean or replace as needed to maintain clean output.

Monitor pressure and temperature levels to prevent overheating or wear.

Schedule periodic servicing to replace worn components with genuine ELGI parts.

Frequently Asked Questions

1. What makes Industrial Elgi Air Compressors different from other piston compressors?

They combine high durability, energy efficiency, and low maintenance, making them suitable for continuous operation in industrial settings.

2. Where can I buy EG Series compressors?

You can purchase them directly from the Air Demand shop.

3. Are ELGI Compressed Air Products energy-efficient?

Yes, they are designed to reduce power consumption while delivering stable and reliable airflow.

4. How often should I service an EG Series compressor?

Regularly check oil and filters, and perform full servicing according to usage frequency to ensure long-term reliability.

5. Can EG Series compressors handle continuous industrial use?

Yes, they are built for continuous heavy-duty operations, making them ideal for workshops and manufacturing facilities.

6. Is technical support available for Industrial Elgi Air Compressors?

Yes, purchasing through Air Demand ensures access to technical advice and genuine spare parts.

7. Are these compressors suitable for small workshops?

Absolutely, the EG Series is versatile enough for small workshops and can scale up to larger industrial requirements.

8. Why should I use genuine ELGI Compressed Air Products for parts?

Using genuine parts guarantees compatibility, optimal performance, and extends the life of your compressor.

How to Choose the Right Industrial Air Compressor for Your Business

Compressed air is the backbone of many industrial operations, from small workshops to large manufacturing plants. Choosing the right air compressor ensures reliability, efficiency, and cost savings. In this guide, we explore the key factors to consider when selecting an industrial air compressor.

1. Understanding Your Air Requirements

Assess the volume of air your operations need (CFM – cubic feet per minute).

Consider operating pressure (PSI) requirements.

Evaluate duty cycles and continuous vs intermittent use.

2. Types of Air Compressors

Rotary Screw Compressors: Efficient for continuous operation, ideal for large-scale industries.

Piston (Reciprocating) Compressors: Perfect for workshops or intermittent usage.

Oil-Free Compressors: Essential where clean air is critical (food, pharmaceuticals).

Oil-Lubricated Compressors: Robust, longer lifespan, suitable for heavy-duty operations.

3. Energy Efficiency Matters

Energy-efficient compressors reduce electricity costs.

Modern rotary screw compressors offer variable speed drives for maximum efficiency.

4. Maintenance and After-Sales Support

Regular maintenance extends compressor lifespan.

Choose a distributor offering comprehensive after-sales support and service contracts.

5. Pneumatic Tools Compatibility

Ensure your air system supports the tools you use.

Consider pressure, airflow, and duty cycle for optimal performance.

Conclusion:

Selecting the right industrial air compressor is critical for productivity, cost efficiency, and long-term reliability. Partnering with an experienced distributor, like Air Demand Ltd, ensures you get tailored solutions, premium equipment, and expert guidance to meet your business needs.

Optional FAQ Section:

Q1: How do I know what size air compressor I need?

A: Calculate your total CFM requirements based on all tools and machinery that will run simultaneously, plus a safety margin.

Q2: What is the difference between oil-free and oil-lubricated compressors?

A: Oil-free compressors provide clean air for sensitive applications, while oil-lubricated units are more durable and suitable for heavy industrial use.

Q3: How often should an industrial air compressor be serviced?

A: Typically, routine maintenance is recommended every 3–6 months, but it depends on usage and the type of compressor.

Piston Ring Compressor: A Key Tool for Safe Engine Assembly

Piston Ring Compressor

A piston ring compressor is an essential tool in engine rebuilding and automotive repair. Whether you’re working on a car, motorcycle, or industrial engine, this simple tool ensures that the piston and piston rings are installed safely into the cylinder without causing mechanical damage.

This article explains what a piston ring compressor is, how it works, its types, and why it is a must-have tool for any mechanic or engine builder.

What Is a Piston Ring Compressor?

A piston ring compressor is a specialized tool designed to compress the piston rings tightly around the piston so it can be inserted smoothly into the engine cylinder.

Without this tool, installing the piston becomes difficult and risky, potentially leading to:

Cracked or broken piston rings

Scratched cylinder walls

Poor engine compression

Reduced engine lifespan

The tool ensures even pressure around the piston rings, allowing the piston to slide into the cylinder effortlessly and safely.

How Does a Piston Ring Compressor Work?

The operation of a piston ring compressor is simple but essential for accuracy and safety:

Place the compressor around the piston, ensuring all rings are fully covered.

Tighten the tool using the integrated key or ratchet until the rings are firmly compressed.

Align the piston with the cylinder so it sits perfectly straight.

Tap the piston lightly using a soft mallet or wooden handle until it slides into the cylinder bore.

The compressor keeps the rings compressed long enough for the piston to be properly inserted without damage.

Types of Piston Ring Compressors

There are several types of piston ring compressors used in different mechanical applications:

1. Adjustable Band Compressors

The most common type, featuring a flexible metal band that tightens around the piston.

Advantages:

Fits many piston sizes

Easy to use

Affordable and widely available

2. Tapered Ring Compressors

A professional-grade conical tool that compresses the rings as the piston slides through it.

Advantages:

Provides perfectly even pressure

Ideal for precision engine work

Drawback:Each cylinder size requires a different tool

3. Ratcheting Compressors

These use a ratchet mechanism for powerful and controlled tightening.

Advantages:

Offers strong and uniform compression

Suitable for larger or high-performance pistons

Why a Piston Ring Compressor Is Important

Using a piston ring compressor ensures:

Safe and damage-free piston installation

Consistent compression pressure for better engine performance

Reduced risk of ring breakage or cylinder scoring

Faster and more efficient engine assembly

Regardless of engine size, this tool plays a critical role in maintaining engine integrity and long-term reliability.

Where Piston Ring Compressors Are Commonly Used

You’ll find piston ring compressors used in:

Automotive workshops

Motorcycle and small engine repair

Heavy machinery maintenance

Engine rebuilding facilities

DIY mechanical projects

Any application involving piston installation benefits from this essential tool.

Why Your Air System Needs a Compressed Air Receiver Tank

Compressed air is the backbone of countless industrial applications — from manufacturing and workshops to automation and assembly lines. While the air compressor often gets all the attention, there is another component that quietly plays a crucial role in system performance: the Compressed Air Receiver.

In this article, we’ll explain what an air receiver is, why it is essential for every compressed air system, and how choosing the right receiver tank can significantly increase efficiency, stability, and safety across your operations.

What Is a Compressed Air Receiver?

A Compressed Air Receiver (also known as an air tank or air storage vessel) is a pressure-rated container designed to:

Store compressed air

Stabilise system pressure

Provide extra capacity during peak demand

Reduce compressor cycling

Improve overall system efficiency

Instead of allowing the compressor to run continuously during pressure fluctuations, the receiver acts as a buffer — storing air when demand is low and releasing it when demand increases.

Why an Air Receiver Is Important for Your System

1. Stabilises Air Pressure

Air demand fluctuates throughout the day. Without a receiver, pressure drops can occur, affecting tool performance and product quality.

The air receiver stores excess compressed air and delivers it instantly during spikes in demand, ensuring stable pressure across the system.

2. Reduces Compressor Cycling

Frequent start-stop cycles place strain on the compressor motor and increase wear.

An air receiver reduces the number of cycles by supplying air during short bursts of demand, allowing the compressor to run more efficiently and with less mechanical stress.

3. Increases Energy Efficiency

Starting a compressor consumes significantly more energy than running steadily.

By reducing start-up cycles and maintaining smoother operation, an air receiver helps lower energy consumption and operational costs.

4. Improves Air Quality and Reduces Moisture

As air cools inside the receiver, moisture naturally condenses and can be drained out.

This removes water from the system before it reaches tools, valves, and downstream equipment — preventing corrosion and extending equipment life.

5. Protects the Air System from Pressure Surges

Air receivers absorb sudden high-demand bursts, preventing pressure shocks that can damage sensitive components and shorten the lifespan of air-powered tools.

Types of Air Receiver Tanks

Depending on available space and system requirements, air receivers typically come in two main styles:

• Vertical Air Receivers

Space-saving

Easier to drain moisture

Suitable for workshops and limited floor areas

• Horizontal Air Receivers

Often paired with compressors

Ideal for large-scale industrial systems

Stable and easy to install in open spaces

Both types serve the same purpose — choosing between them depends on your space, layout, and accessibility needs.

How to Choose the Right Air Receiver Size

Selecting the correct size is critical for maximum performance. Consider:

1. Compressor Capacity (CFM)

A common rule of thumb:

Receiver volume (litres) = 6–10 times the compressor’s free air delivery.

2. Working Pressure

Always ensure the receiver is pressure-rated to handle your compressor’s maximum system pressure.

3. Application Type

High-demand applications → Larger tanks

Steady, low-variation systems → Standard size tanks

4. Space Availability

Vertical tanks are ideal when floor space is limited.

Where Air Receivers Are Commonly Used

You will find air receivers in almost every industry, including:

Manufacturing plants

Metal workshops

Automotive repair centres

Packaging lines

Food & beverage processing

Energy and process industries

Construction and pneumatic tool operations

Any application with fluctuating air demand benefits significantly from a receiver tank.

Why Choose Air Receivers from Air Demand UK?

At AirDemand.co.uk, you’ll find high-quality, durable compressed air receivers suitable for a wide range of industrial applications. Our tanks are:

Pressure-rated and built to industry standards

Available in multiple sizes and orientations

Designed for efficiency, safety, and long-term reliability

Suitable for compressors of all brands

By pairing your compressor with the right air receiver, you’ll experience smoother operation, reduced energy costs, and longer equipment life.

Preventing Air Leaks

Preventing Air Leaks: Why Regular Maintenance Is Key to Avoiding Costly Downtime

By Jason Smith, Engineering Director - Air Demand Ltd

As someone who has spent over 20 years working hands-on with air compressors and pneumatic systems, I’ve seen firsthand how much of a silent profit killer air leaks can be. Many businesses underestimate just how much energy and money are lost every year through poorly maintained systems — not to mention the production downtime and stress they cause when they lead to pressure drops or equipment failures.

At Air Demand Ltd, we help companies across Yorkshire identify and eliminate leaks before they become expensive problems. In this post, I’ll explain why air leaks happen, how to spot them early, and why ongoing maintenance is the most cost-effective strategy to keep your systems efficient and reliable.

The Hidden Cost of Air Leaks

Compressed air is one of the most expensive utilities in any industrial environment — and leaks waste a surprising amount of it. A single 3mm leak can cost hundreds of pounds per year in wasted electricity.

When your system has multiple leaks, compressors have to run longer to maintain pressure, consuming more energy and putting extra strain on components. Over time, that stress leads to more breakdowns, shorter compressor life, and unexpected downtime that halts production.

💡 In short: air leaks don’t just waste air — they waste money, energy, and productivity.

Why Leaks Occur

Air leaks are common in almost every facility, but they’re usually the result of:

* Worn or cracked hoses and seals

* Loose pipe fittings or joints

* Corrosion in older systems

* Poor installation practices

* Vibration or mechanical movement causing gradual loosening

Even brand-new systems can develop leaks within months if fittings aren’t properly torqued or if pipework isn’t installed correctly.

How to Detect Air Leaks

In my experience, the most effective approach combines routine inspections with professional leak detection equipment.

Here’s what to look (and listen) for:

* Hissing or whistling sounds near fittings, valves, or hoses

* Unexpected compressor cycling (compressor running more often than normal)

* Pressure drops at the point of use

* Reduced performance from pneumatic tools or machinery

At Air Demand, we use our years of experience and tools to check for the smallest of leaks.

Maintenance: The Best Prevention

Routine maintenance is the single most effective way to keep leaks from developing.

That means:

* Checking all fittings, hoses, and couplings during service visits

* Replacing seals and gaskets before they fail

* Cleaning and tightening connections regularly

* Reviewing your compressor’s load/unload cycles to ensure efficiency

A scheduled maintenance plan not only prevents leaks but also helps identify early signs of wear before they turn into costly downtime.

Why Partner with Air Demand Ltd

At Air Demand Ltd, our engineer-led approach means we go beyond basic service - we provide technical insight and proactive system care.

Our services include:

✅ Air Compressor Sales & Installation

✅ Pneumatic Equipment & Parts Supply

✅ Air System Audits & Leak Detection

✅ Preventative Maintenance Contracts

✅ Pipework Design & Installation

We believe maintenance isn’t an expense - it’s an investment in uptime, efficiency, and peace of mind.

Final Thoughts

After a long time in the pneumatic industry, one thing has become clear: companies that take air leaks seriously save more in the long run. They experience fewer breakdowns, better performance, and lower energy bills.

If you haven’t had your system checked recently, now’s the time. A simple inspection could reveal leaks that are quietly costing your business thousands each year.

📞 Contact Air Demand Ltd today for a professional air system health check or leak detection survey.

Visit www.airdemand.co.uk or call us to book your inspection on 07403106325

The Future of the Pneumatic Industry: What’s Ahead in the Next 5 Years and How Air Demand Can Help You Prepare

The pneumatic industry has long been a backbone of various sectors, from manufacturing and automotive to construction and agriculture. As technology continues to evolve, the pneumatic sector is experiencing a wave of change that will have a significant impact on businesses across the globe. In the next five years, we can expect innovations in automation, energy efficiency, regulatory compliance, and worker safety, all of which will reshape the way pneumatic systems are designed, used, and maintained.

At Air Demand, we understand the importance of staying ahead of these developments. Here’s a look at some of the key trends that will define the future of the pneumatic industry and how we can help your company prepare for the upcoming changes.

1. The Rise of Automation and Smart Pneumatics

The trend toward automation in industrial settings is growing rapidly, and the pneumatic industry is no exception. Smart pneumatics, integrated with sensors, IoT (Internet of Things) devices, and predictive analytics, are set to revolutionize the way pneumatic systems operate. These systems can collect data in real time, adjust pressure levels, optimize energy usage, and even predict when maintenance is needed before issues arise.

How Air Demand Can Help: Air Demand is committed to providing cutting-edge pneumatic solutions that incorporate automation and smart technology. Our range of intelligent systems can help your business embrace the future of automation, ensuring smoother operations, reduced downtime, and increased productivity.

2. Stricter Environmental Regulations and Energy Efficiency Standards

As governments across the world impose stricter environmental regulations, businesses are being urged to minimize their carbon footprint and improve energy efficiency. Pneumatic systems, often reliant on compressed air, can be a significant source of energy consumption if not managed properly. In the next five years, we expect regulations to become even more stringent, pushing companies to adopt energy-efficient solutions.

How Air Demand Can Help: At Air Demand, we specialize in energy-efficient pneumatic solutions that help businesses comply with environmental regulations while reducing operational costs. Our expert team can work with you to assess your current systems, identify energy-saving opportunities, and implement solutions that optimize air consumption without compromising performance.

3. Enhanced Worker Safety and Ergonomics

Safety in the workplace will continue to be a top priority in the years to come. As pneumatic systems become more advanced, new safety standards will be introduced to protect workers from accidents related to compressed air and machinery. Additionally, there will be a greater emphasis on ergonomics to reduce the physical strain on employees working with pneumatic tools and equipment.

How Air Demand Can Help: We prioritize worker safety and ergonomics at Air Demand. Our products meet or exceed the latest safety standards, providing you with peace of mind knowing your pneumatic systems are safe for your team to use. We also offer ergonomic solutions designed to reduce strain on workers, enhancing comfort and productivity.

4. Advancements in Materials and Durability

In the next five years, we can expect advancements in materials used in pneumatic systems. The development of more durable, lightweight, and corrosion-resistant materials will extend the lifespan of pneumatic equipment and improve performance. This shift will help businesses reduce maintenance costs and enhance the longevity of their equipment.

How Air Demand Can Help: Air Demand stays ahead of the curve when it comes to material innovation. Our range of high-quality pneumatic components is designed to withstand the harshest environments while maintaining superior performance. By investing in our advanced materials, your company can enjoy long-lasting, reliable pneumatic systems that stand the test of time.

5. Evolving Industry Standards and Compliance

As new technologies emerge, industry standards and regulations will evolve to ensure the safety, sustainability, and efficiency of pneumatic systems. In the coming years, businesses will need to stay on top of these regulatory changes to avoid penalties and maintain their operations smoothly.

How Air Demand Can Help: Navigating evolving industry standards can be complex, but at Air Demand, we are here to guide you. We keep a close eye on emerging regulations and work closely with you to ensure your systems are fully compliant with the latest standards. Whether it’s energy efficiency, safety protocols, or environmental impact, we’ll help you stay ahead of the curve.

Conclusion

The future of the pneumatic industry is full of exciting developments, from automation and energy efficiency to enhanced worker safety and evolving regulations. At Air Demand, we are dedicated to helping your business prepare for these changes and navigate the future with confidence. Our innovative products, expert services, and commitment to sustainability will ensure that your pneumatic systems remain reliable, efficient, and compliant in the years to come.

Ready to prepare for the future? Contact Air Demand today and let us help you future-proof your business with cutting-edge pneumatic solutions.